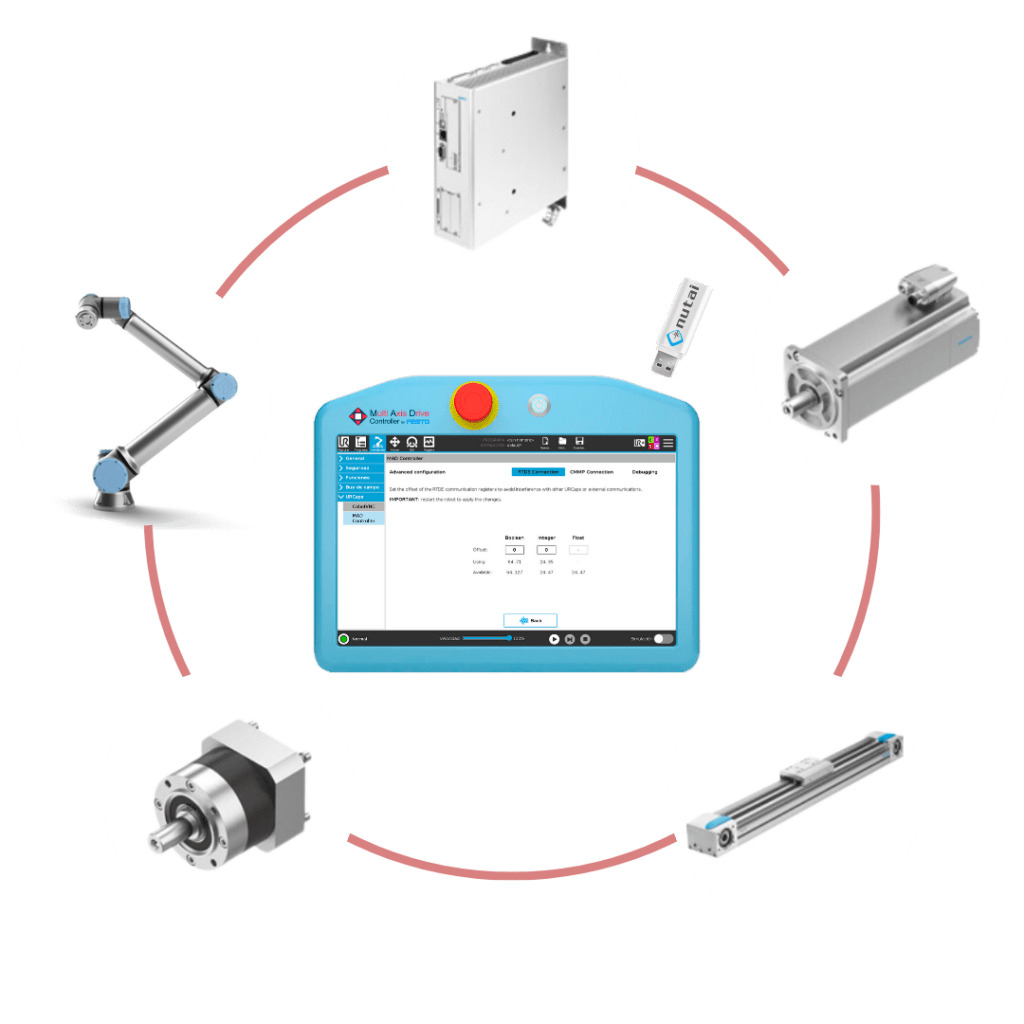

MADController is a URCap software that allows control of up to 4 external FESTO axes directly from the UR robot’s Teach Pendant. It enables movement of the axes to predefined points without the need for additional programming, eliminating the dependence on PLCs or HMIs. Ideal for seamless integration of rotary and linear axes, enhancing servo control capabilities.

EXTEND YOUR UR ROBOT’S REACH WITH UP TO 4 ADDITIONAL EXTERNAL AXES

MADController is a URCap approved by Universal Robots, ensuring the highest standards of quality and safety in collaborative robotics

Usage alternatives for external axis control

Practical applications of Multi Axis Drive

Palletizing

Material Handling

Loading and Unloading

Material Removal

Quality Inspection

Dispensing

Extend your UR’s reach from the Mad Controller interface

Technical Requirements

- Universal Robots e-Series (PolyScope 5.3.0 or higher, soon available for CB-Series)

- FESTO motor controller(s) CMMT-AS/ST and CMMP-AS

- Real-Time Data Exchange (RTDE) Connection

HOW DOES MAD Controller WORK?

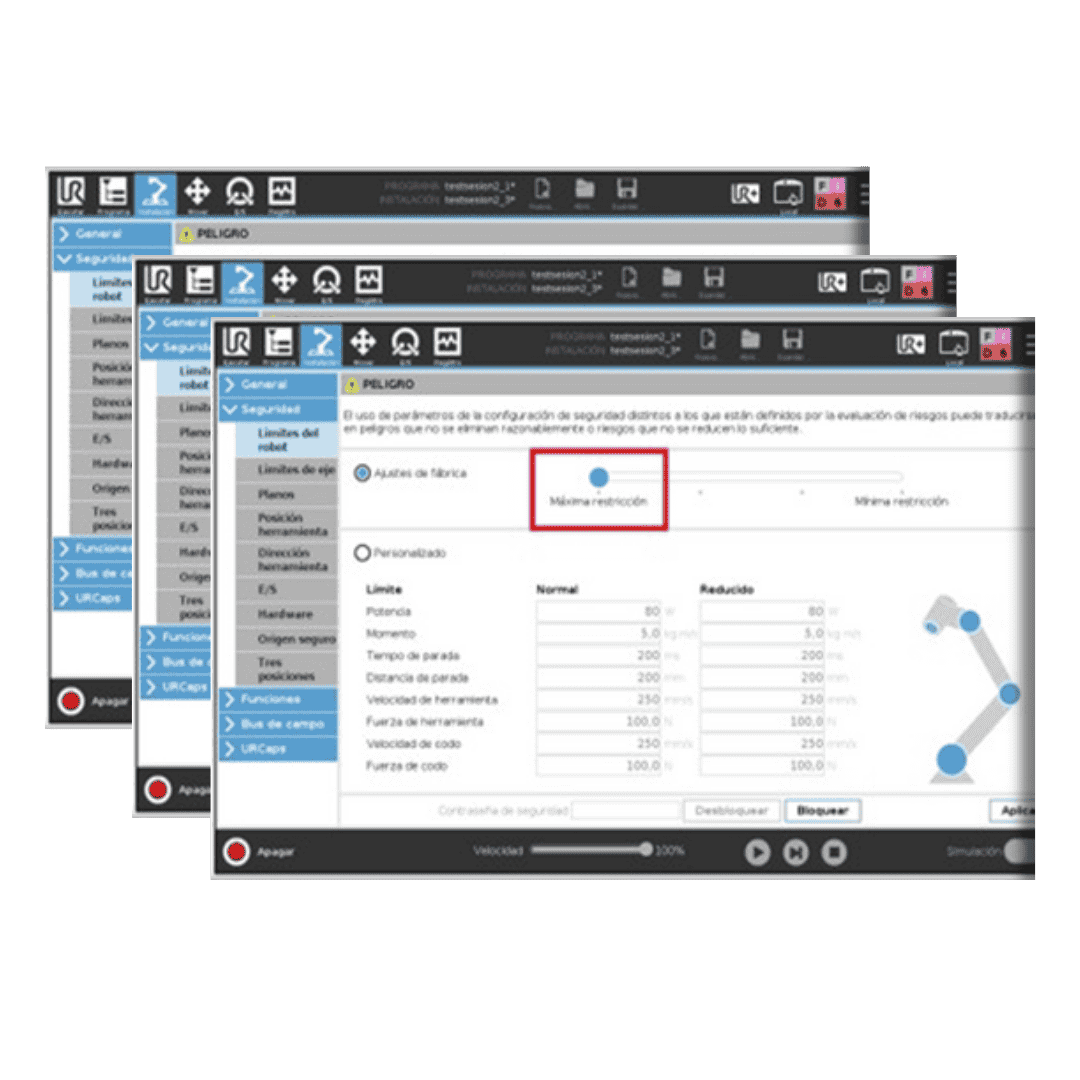

At NUTAI, we have designed MAD Controller to ensure its integration and operation are as simple and efficient as possible. Below, we outline the steps to get MAD Controller up and running, so you can start enjoying its benefits in your collaborative robotics operations.

Install MAD Controller in 3 Steps

Verification of Stroke, Speed, Acceleration, and Motor Controller Configuration

Installation of the MAD Controller URCap and License Activation, etc.

Movement Point Configuration and Safety Connections

sSAFETY CONSIDERATIONS and Best Practices

Before performing any movement, it is essential to check for collision risks. Handling of components should only be carried out by qualified technical personnel. In case of component replacement, a Home operation must be executed, and the saved points should be verified. Additionally, it is important to perform regular and proper maintenance of the mechanical components. If the robot is mounted on one or more axes, it is recommended to use High-Flex type flexible cabling.

Downloads Area

Frequently Asked Questions (FAQ)

¿Puedo controlar más de un robot con MAD Controller?

MAD Controller está diseñado para controlar un solo robot a la vez.

¿Es necesario tener conocimientos de programación para configurar MAD Controller?

No, MAD Controller permite configurar puntos de movimiento de forma intuitiva sin necesidad de programación.

¿Qué ejes externos son compatibles con MAD Controller?

MAD Controller trabaja con el controlador de Festo y toda su gama de ejes lineales. También es compatible con otras marcas de ejes, además de con mesas giratorias, sistemas de almacenamiento automático, transportadores, entre otros.

¿Se puede utilizar MAD Controller en robots de otras marcas además de Universal Robots?

Actualmente, MAD Controller está certificado y optimizado para su uso con robots Universal Robots e-Series.

OUR CLIENTS