What Is Industrial Retooling and Why Is It Key?

Updating machinery and production lines is a constant necessity in fast-evolving industrial environments. However, many companies do not require a full replacement of their systems. This is where retooling comes into play.

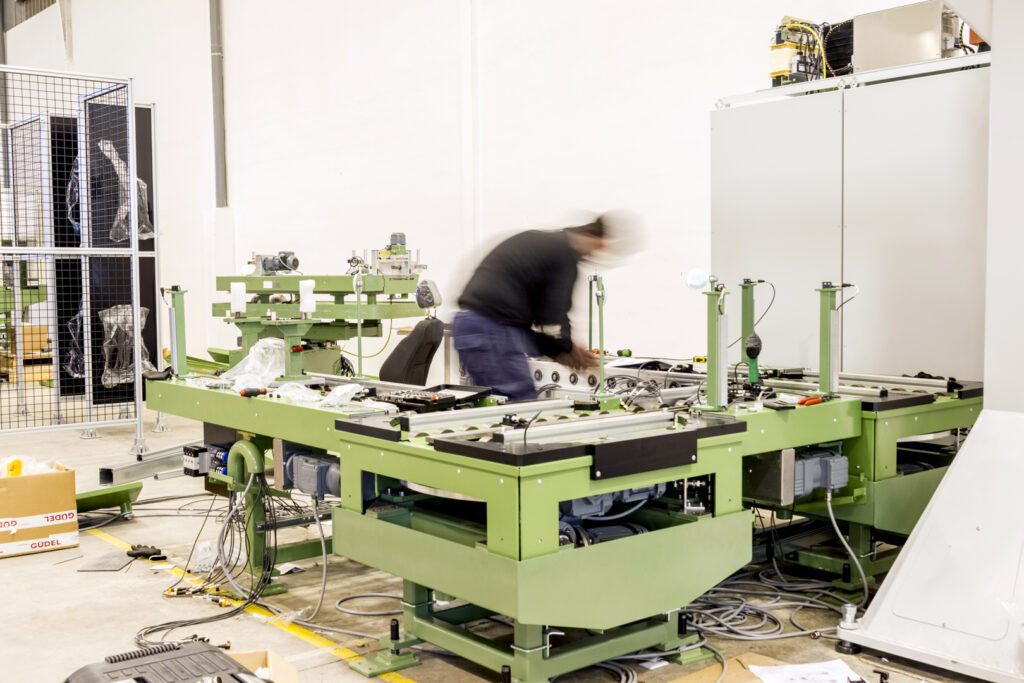

In industrial automation, retooling refers to the process of adapting or refurbishing machinery, production lines, or automated systems in order to improve performance, introduce new functionalities, or manufacture different products. Unlike a complete equipment replacement, retooling focuses on preserving what already works, updating only what is necessary.

At NUTAI, we design retooling solutions that allow existing lines to be modernized by integrating new products and, most importantly, adapting processes to current requirements.

What Does Retooling Involve?

This process can range from changing or redesigning tooling and workstations to more complex modifications, such as PLC reprogramming, sensor integration, or adapting a robotic station.

Retooling is useful in scenarios such as:

How Do We Approach Retooling at NUTAI?

Looking to Upgrade Your Line?

If your plant needs to adapt to new products, increase efficiency, or incorporate technology without replacing the entire line, retooling may be the right solution.

At NUTAI we design tailor-made solutions. Shall we talk?