Predictive maintenance is an advanced strategy used to anticipate when equipment is likely to fail, allowing interventions before a problem occurs. By leveraging advanced algorithms, it helps analyze large volumes of data automatically, accurately, and in real time. AI enables the identification of patterns, more precise prediction of future failures, and optimization of maintenance scheduling to avoid unnecessary downtime or critical failures.

Advanced data analytics

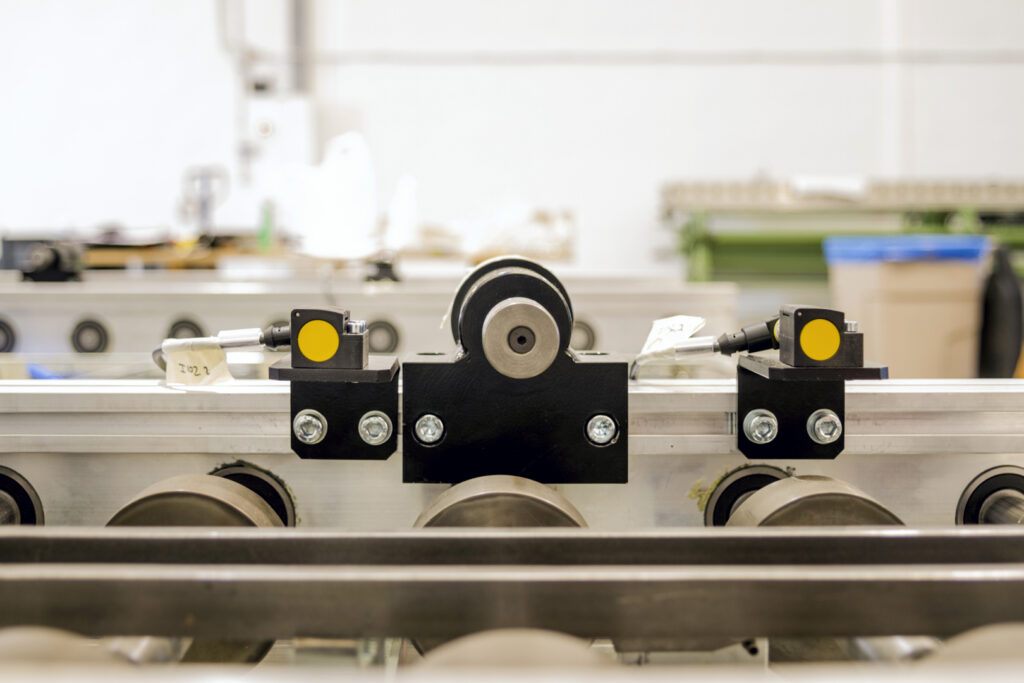

AI can process large amounts of data collected from multiple sensors in machines (such as temperature, vibration, noise, pressure, etc.). This includes the use of algorithms to analyze historical data and detect anomalies that may indicate potential failures.

More accurate failure prediction

Through predictive algorithms, AI can foresee the exact moment when equipment might fail. This is achieved by identifying hidden correlations and subtle anomalies that humans or conventional systems might overlook.

Optimization of equipment lifecycle

AI not only predicts when a component will fail, but also recommends the best time to perform maintenance with minimal impact on production, optimizing resources and extending the useful life of assets.

Automation in decision-making

AI-based predictive maintenance systems can make automated decisions, such as sending alerts, scheduling maintenance tasks, or initiating corrective actions without human intervention.

AI-powered digital twins

A digital twin is a virtual replica of a physical piece of equipment that uses real-time data to simulate its behavior. When combined with AI, the digital twin can analyze equipment performance under various conditions and predict its wear or failure in different operational scenarios.

Custom solutions

We design and manufacture custom technology tailored to your industrial needs.

Innovation, precision, and quality within your reach.