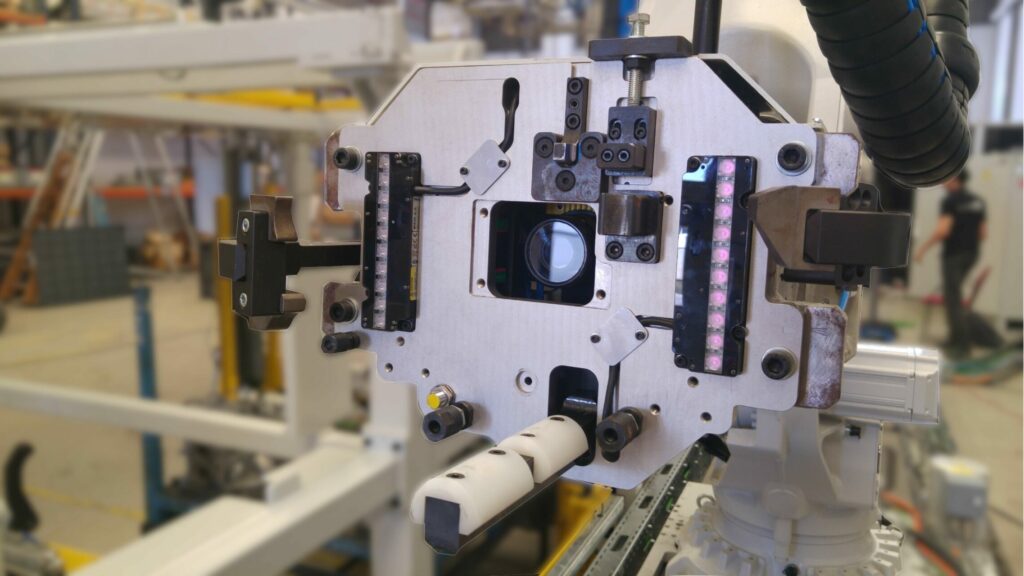

In industrial environments, 2D and 3D vision-guided technology is a key enabler for optimizing manufacturing, assembly, and quality control processes. By using high-precision cameras and advanced image processing algorithms, these systems enable the accurate identification, localization, and manipulation of parts—typically through robotic systems.

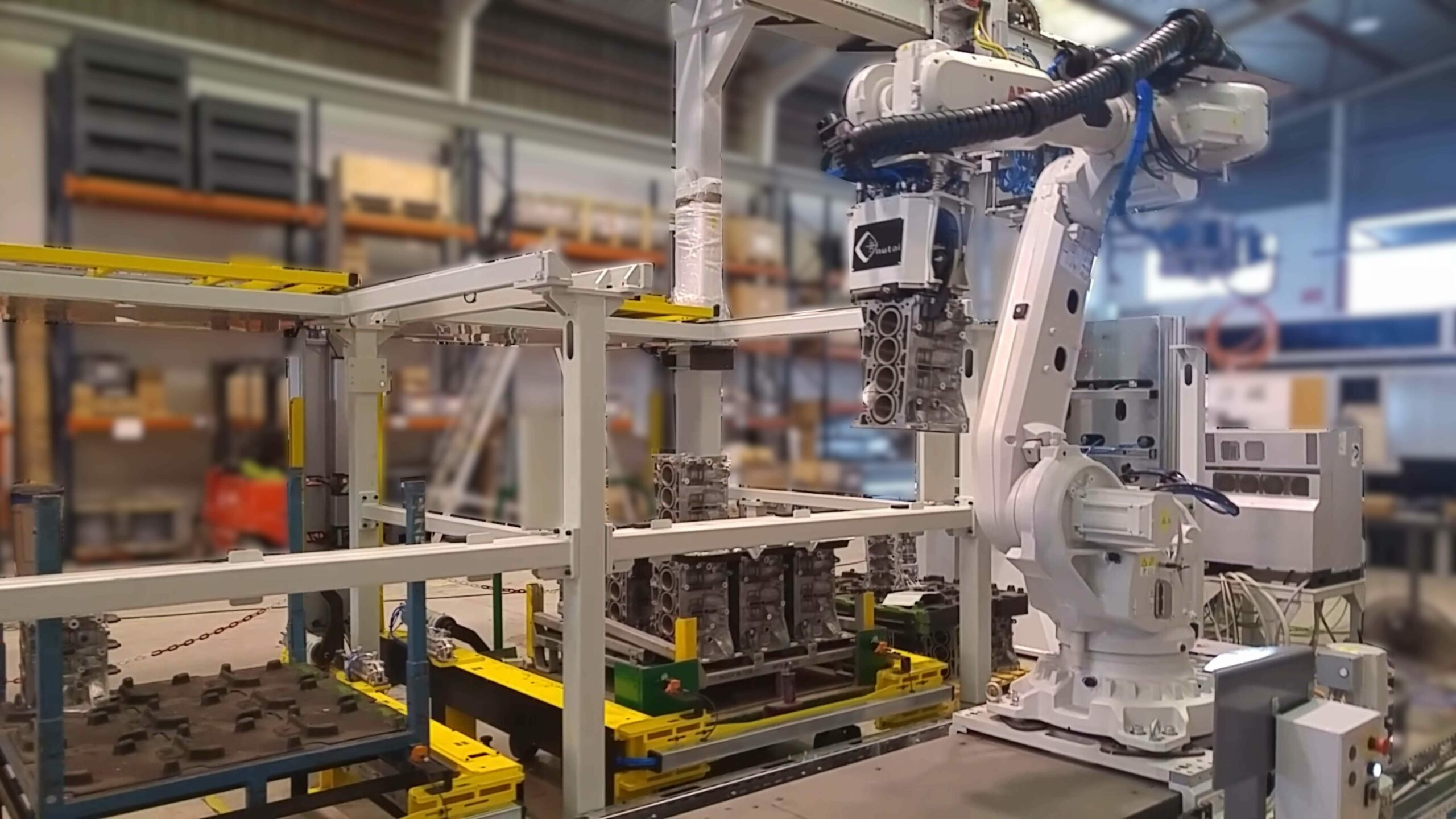

2D and 3D vision guidance enables real-time object detection, providing full spatial coordinates (X, Y, Z) and rotational data (Rx, Ry, Rz) for precise picking operations. This technology is applied across a wide range of industrial scenarios, such as:

2D Vision Guidance

It is based on flat images captured by industrial vision cameras and enables the identification of shapes, edges, codes, and surface features of objects.

It is used in applications where the height or depth of the object is not a critical factor, such as label recognition, barcode scanning, and part orientation on conveyor belts.

3D Vision Guidance

It uses depth sensors or multiple cameras to capture three-dimensional information of the environment, allowing volume measurement, height variation detection, and more precise positioning of objects in a three-dimensional space.

It is ideal for applications where depth position or object shape is critical, such as complex part assembly, palletizing, and robot guidance in dynamic environments.

We design and manufacture custom technology tailored to industrial needs.

Innovation, precision, and quality within your reach.

Our Experience in Action

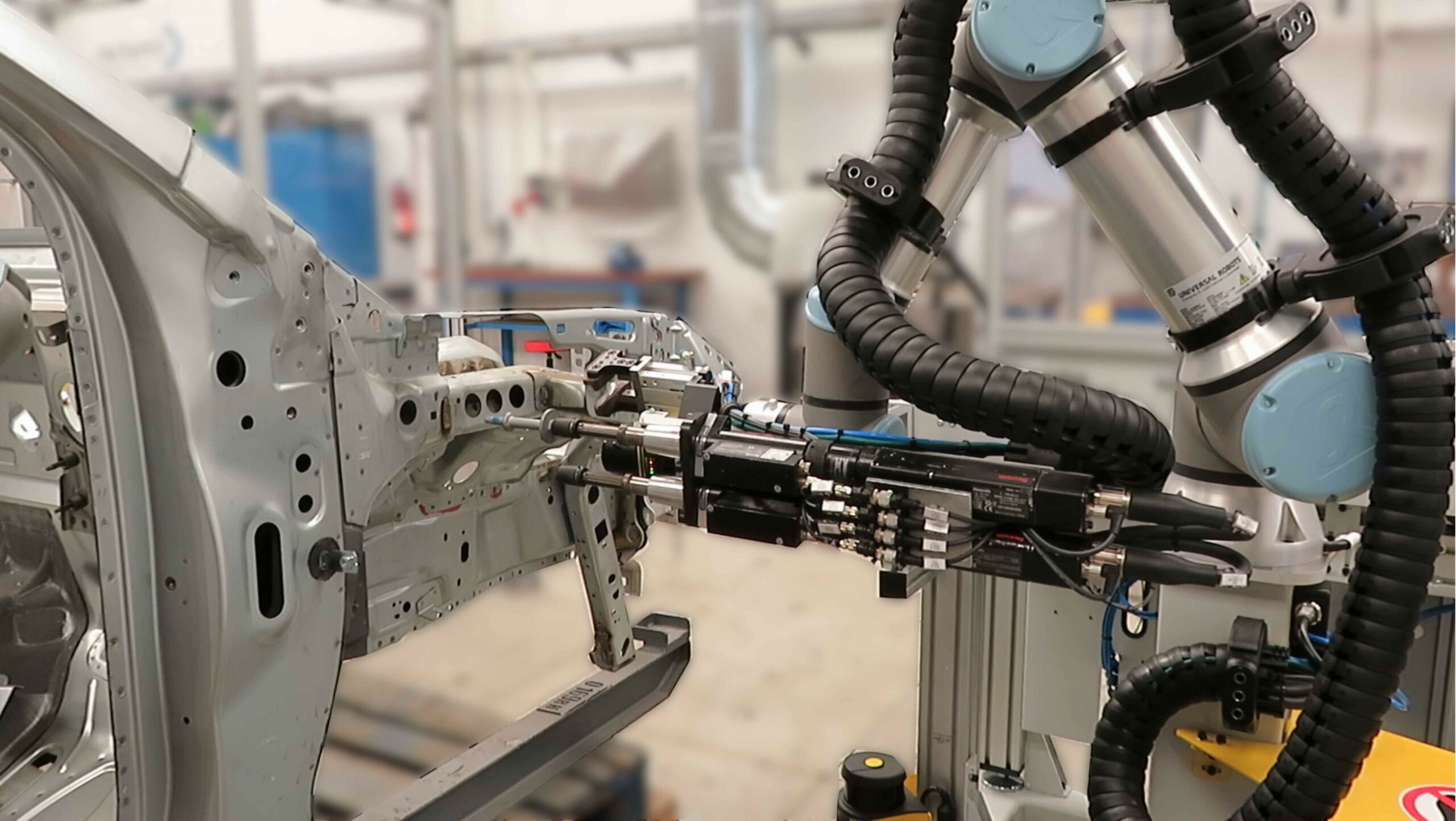

Vision-Guided Robotic System for Hood Hinge Screwdriving

Guidance System – Automotive Sector