In the industry, automated visual inspection for defect detection is a key tool to ensure the aesthetic, surface, and functional quality of products. Thanks to the combination of machine vision, 3D sensors, and artificial intelligence, these systems detect and analyze defects in parts and components with high precision, preventing defective products and optimizing production processes.

2D Surface Defects

3D Surface Defects

We design and manufacture customized technology for industrial needs.

Innovation, precision, and quality within your reach.

Applications in Industry

Camshafts: Quality control of critical parts through automated inspection

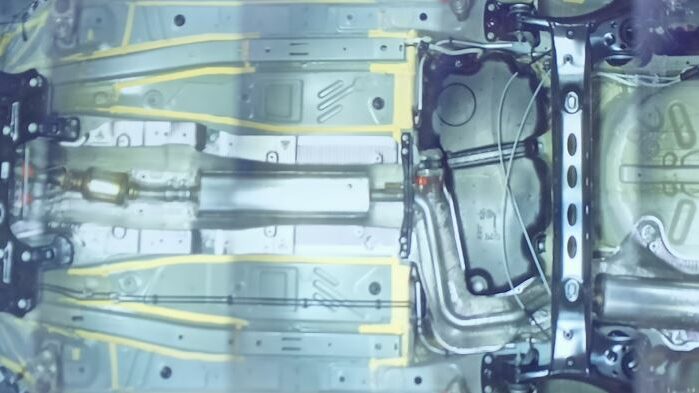

Engines and mechanical components: Defect detection in engines using cobots with machine vision