The Digital Transformation of Quality Control

In industry, quality control has always been a strategic pillar. However, traditional methods based on manual inspections are often costly, slow, and difficult to scale.

Today, in-line quality inspection is transforming this process: machine vision systems, smart sensors, and connected platforms allow defects to be detected in real time, directly on the production line. This results in fewer errors, less waste, and improved traceability—bringing security to both the company and the end customer.

Artificial Intelligence and Machine Learning

Artificial intelligence in manufacturing is increasingly applied to in-line quality inspection. These systems learn from thousands of images and production patterns to identify defects invisible to the human eye.

Integration of NUTAI Solutions in Quality Inspection

At NUTAI, we have developed advanced solutions for quality inspection across different industrial sectors.

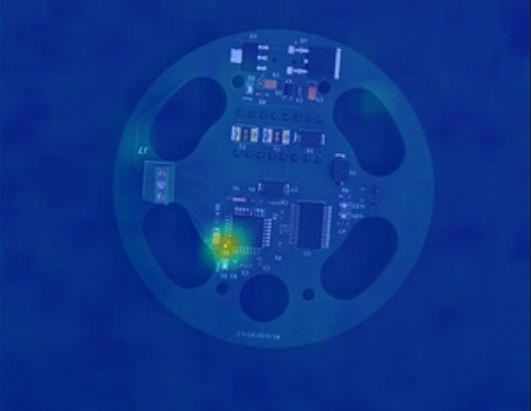

nqInspect

A solution designed for detecting surface defects and appearance anomalies in all types of products and materials. This system optimizes inspection processes and ensures 100% product quality, enabling real-time control while reducing human error.

SIXHEAD

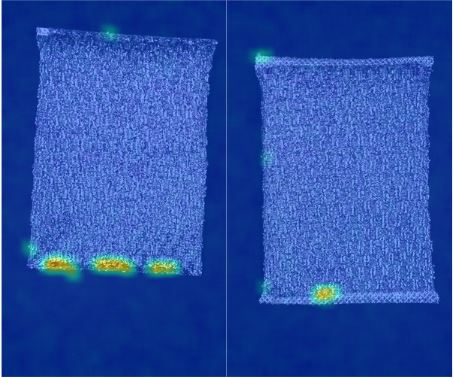

A specialized system for inspecting surface defects and sheet metal quality control, powered by artificial intelligence developed by NUTAI (NQInspect). SIXHead SIXHead maximizes contrast and minimizes noise during image acquisition, allowing highly precise real-time defect detection.

Both systems are clear examples of how digitalization and artificial intelligence applied to in-line quality inspection enable companies to guarantee flawless products, optimize processes, and improve industrial efficiency.

Use Cases by Industry Sector

Automotive

Quality is a critical requirement in every part. In-line quality inspection detects imperfections in bodywork, welds, and safety components. This helps manufacturers reduce risks and ensure higher quality.

Sponges (Cleaning Products)

Consumers expect consistent and durable products. Machine vision systems verify the uniformity, size, color, and packaging of sponges directly on the production line, preventing defects and ensuring each one meets quality standards.

Electrónica

In a circuit, a defective solder can cause massive failures. With AI applied to manufacturing, plants can identify micro-defects in boards and components, ensuring the reliability of equipment later used in telecommunications, energy, or medical devices.

KPIs to Measure the Success of In-Line Inspection

The implementation of these systems is not only measured in efficiency but also through key indicators such as:

A good quality control system should show clear improvements in these three areas within the first months of operation.

In-line quality inspection is not just a trend—it is a competitive necessity in Industry 4.0. Adopting digitalization, AI, and machine vision technologies allows companies to guarantee quality, reduce costs, and improve the end-customer experience.

At NUTAI, we offer solutions such as NQInspect and SIXHead, designed to bring machine vision and artificial intelligence directly to your production line—ensuring total quality and real-time efficiency.

👉 If you want to discover how our solutions can improve your company’s quality and productivity, our team of experts is ready to assist you.