Intelligent digitized computer vision system for defect detection and quality control in the die-cutting sector

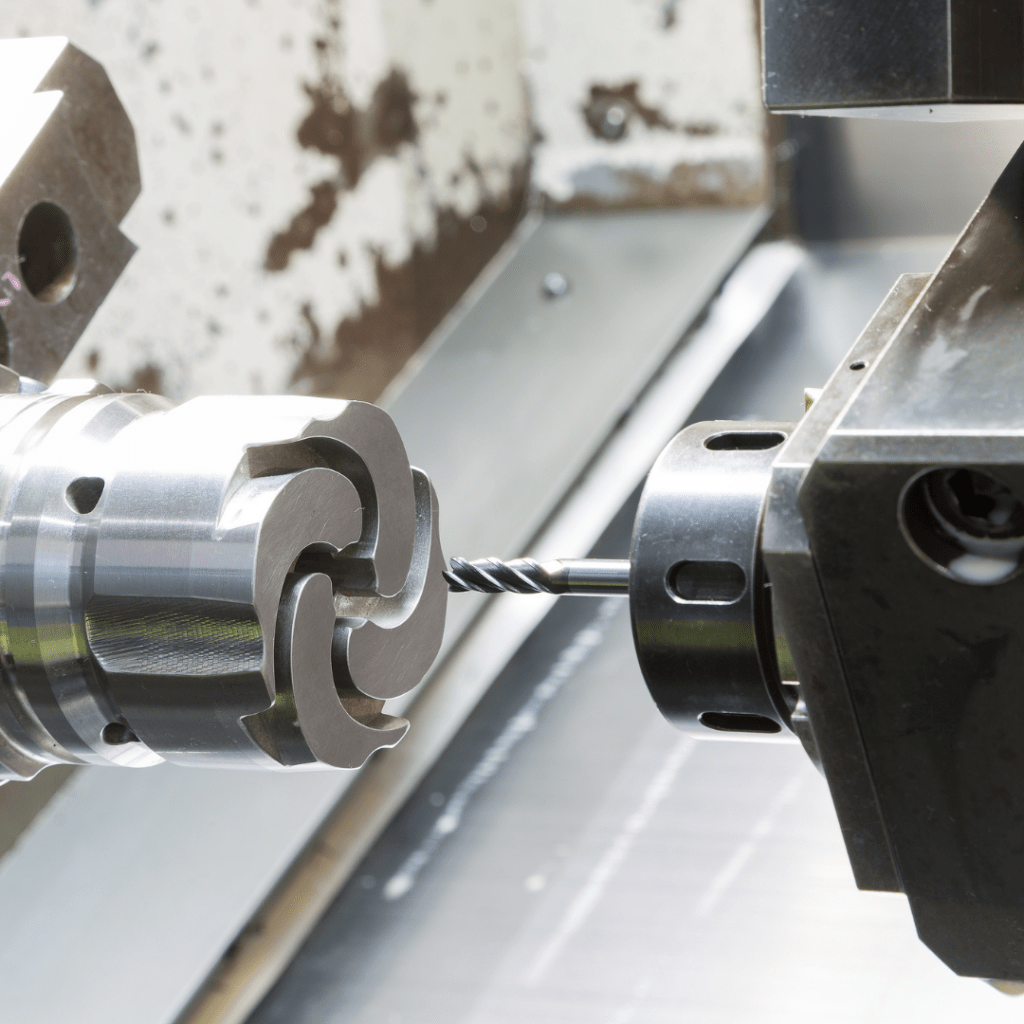

The VISITRON project, jointly coordinated by the Automotive Cluster of Catalonia (CIAC) and the Automotive Cluster of the Valencian Community (AVIA), and carried out by companies associated with the automotive industry—LEMEC, NUTAI, and OMNIELECTRIC—aims to develop a technological proposal to initially research vision technology and subsequently develop innovative automated computer vision systems within the automotive sector. This will be achieved through the digitization of inspection and quality control processes, seeking to optimize and reduce incidents within the production lines of the die-cutting sector.

To carry out this project, various industrial and engineering companies are participating, pooling knowledge and generating synergies from each discipline to achieve the digital transformation of the sector based on the development of innovative and cutting-edge technologies.

Furthermore, through digitalization, production processes can be monitored in real time, allowing for more efficient and faster identification and resolution of potential incidents. It also enables the integration of quality control systems with other processes in the production chain, allowing for greater automation, reduction of human errors, and improved energy efficiency.

The project is funded by the 2023 call for Innovative Business Groups (Exp. No. AEI-010500-2023-239) from the Ministry of Industry and Tourism (MINTUR).