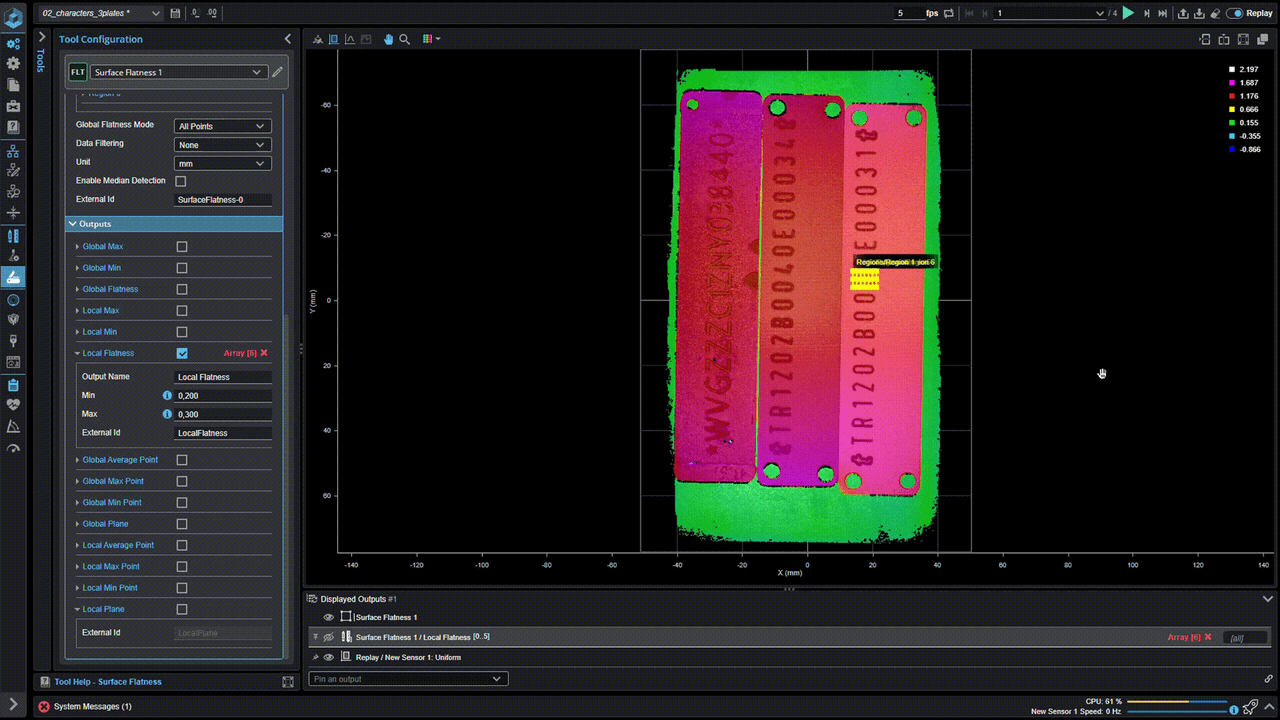

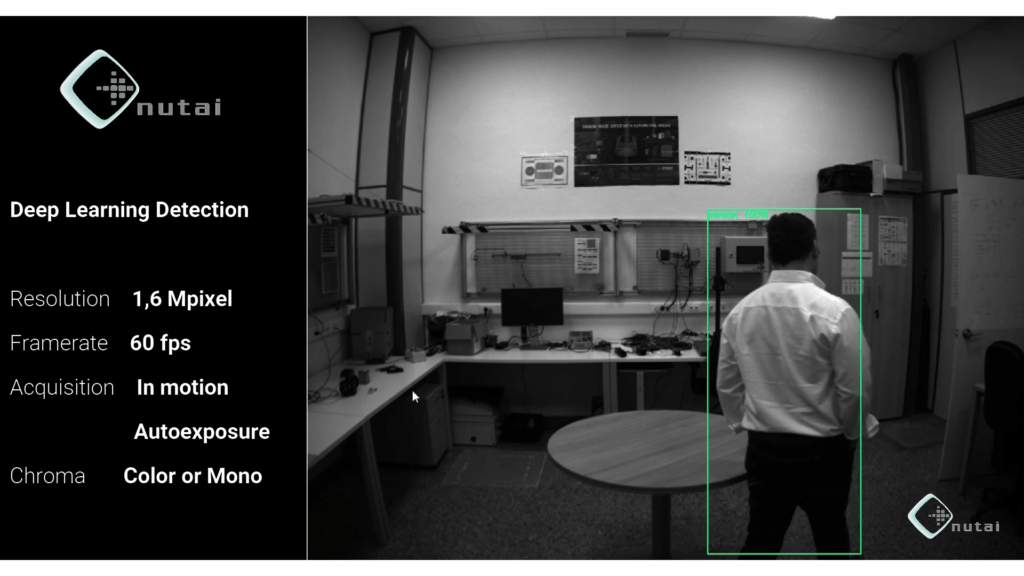

En Nutai, nos especializamos en el desarrollo de soluciones avanzadas de inteligencia artificial (IA) para transformar y optimizar los procesos industriales. Nuestro equipo de expertos combina tecnologías de vanguardia como el machine learning, la detección de defectos, el deep learning y el mantenimiento predictivo para ofrecer soluciones innovadoras y eficientes.

En NUTAI, estamos comprometidos con revolucionar la industria de la automatización industrial a través de soluciones avanzadas de inteligencia artificial. Nuestro objetivo es mejorar la eficiencia, precisión y seguridad de los procesos industriales mediante la implementación de tecnologías de vanguardia como machine learning, deep learning, detección de defectos y mantenimiento predictivo.